Certified Excellence in Every Component

At Rivimetal, quality is not just a process—it’s a commitment. Our Quality Management System is certified according to ISO 9001:2015, ensuring compliance with international standards for consistency, process control, and continual improvement.

We align our production and quality planning processes with AIAG Core Tools (APQP, PPAP, FMEA, MSA, SPC) and incorporate customer-specific requirements derived from IATF 16949 and VDA guidelines, especially for the automotive and defense sectors.

This ensures each component meets stringent technical, functional, and regulatory requirements.

Our Approach to Quality

1. Advanced Product Quality Planning (APQP)

Proactive planning for flawless execution.

We follow the APQP methodology to plan and validate every stage of production. From feasibility to final approval, our teams ensure that all process risks are addressed and quality objectives are built into the product from day one.

2. Failure Mode & Effects Analysis (PFMEA)

Preventing issues before they happen.

By applying PFMEA in the early phases of each project, we proactively identify potential failures and implement safeguards—delivering consistent results and dependable components across all industries we serve.

Quality Tools and Methods We Utilize

Flowchart Development

Process flowcharts define manufacturing and inspection steps with clear control points for each project.

FMEA

Applied during design and process planning to identify potential failure modes and implement preventive actions.

Control Plans

Documented plans outlining critical characteristics, tolerances, inspection methods, and reaction strategies.

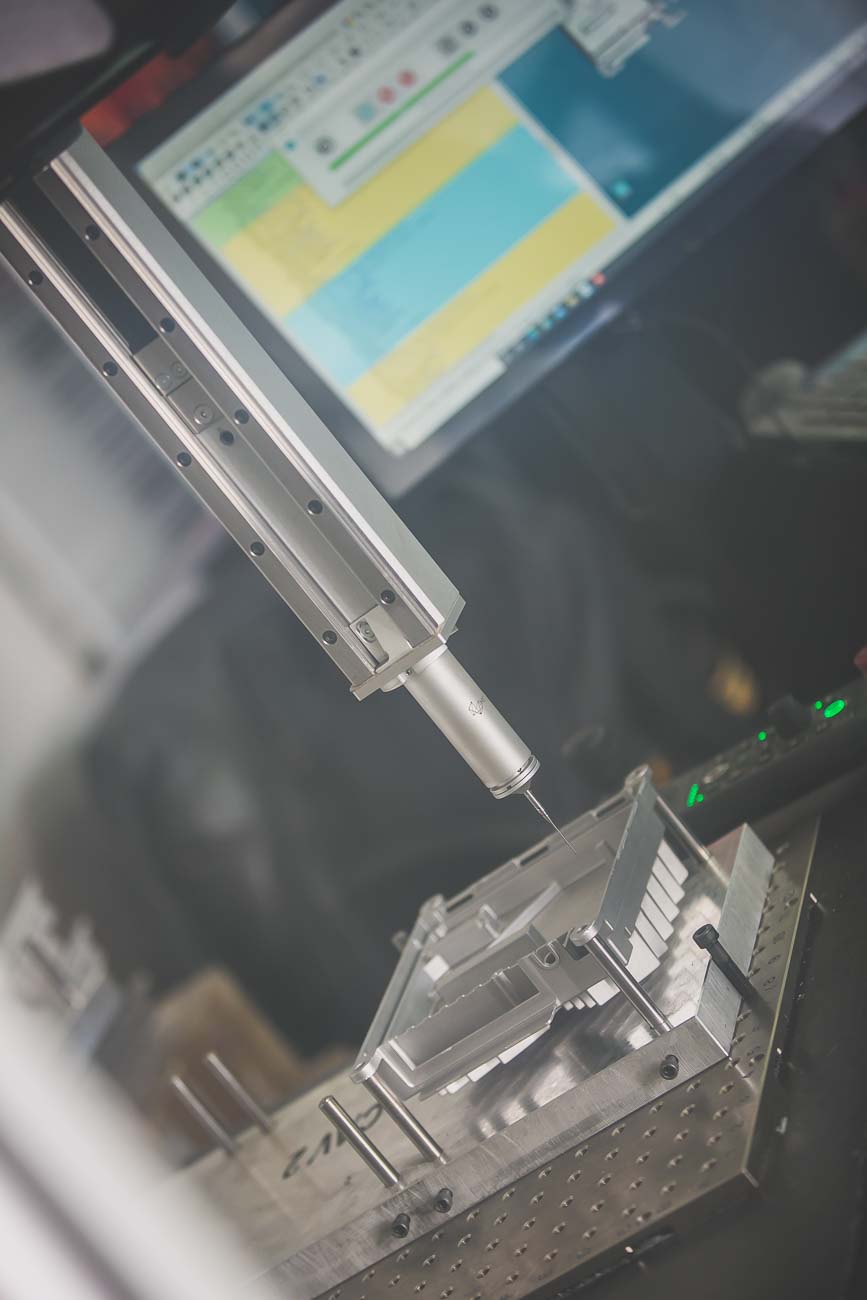

First Article Inspection (FAI)

Conducted at tool release using full dimensional reports to validate the accuracy of initial production runs.

Statistical Process Control (SPC)

Real-time monitoring of critical parameters ensures process stability and data-driven decision-making.

Measurement System Analysis (MSA)

Confirms the capability and repeatability of measurement equipment and operators.

Solving Problems at the Root

At Rivimetal, we believe that consistent quality depends on addressing problems at their source. Our team uses a structured set of tools to drive continuous improvement and eliminate repeat issues:

8D Reports

Structured, team-based problem-solving for complex issues.

5 Whys

Simple and effective technique to uncover the root cause.

Ishikawa Diagrams

Visual mapping of contributing causes across multiple categories.

Pareto Charts

Focused attention on the issues with the greatest impact.

Auditing and Continuous Improvement

At Rivimetal, we believe in continuous improvement through regular audits and performance evaluations:

Internal ISO 9001 and ISO 14001

Ensuring compliance with international quality and environmental standards.

Internal VDA 6.3 Audits

Applied by trained internal auditors to evaluate manufacturing and support processes using automotive industry benchmarks.

Client Evaluation Scorecards

Monitoring customer feedback and performance metrics for ongoing improvement.

Product & Supplier Audits

Periodic audits of key suppliers and critical products ensure alignment with technical and quality expectations.

Client-Conducted Audits

We support open collaboration with customers, facilitating audits and addressing feedback through transparent communication and joint improvement plans.

Let’s Build with Precision Together

Partner with Rivimetal for die casting solutions that redefine industry standards.

Contact